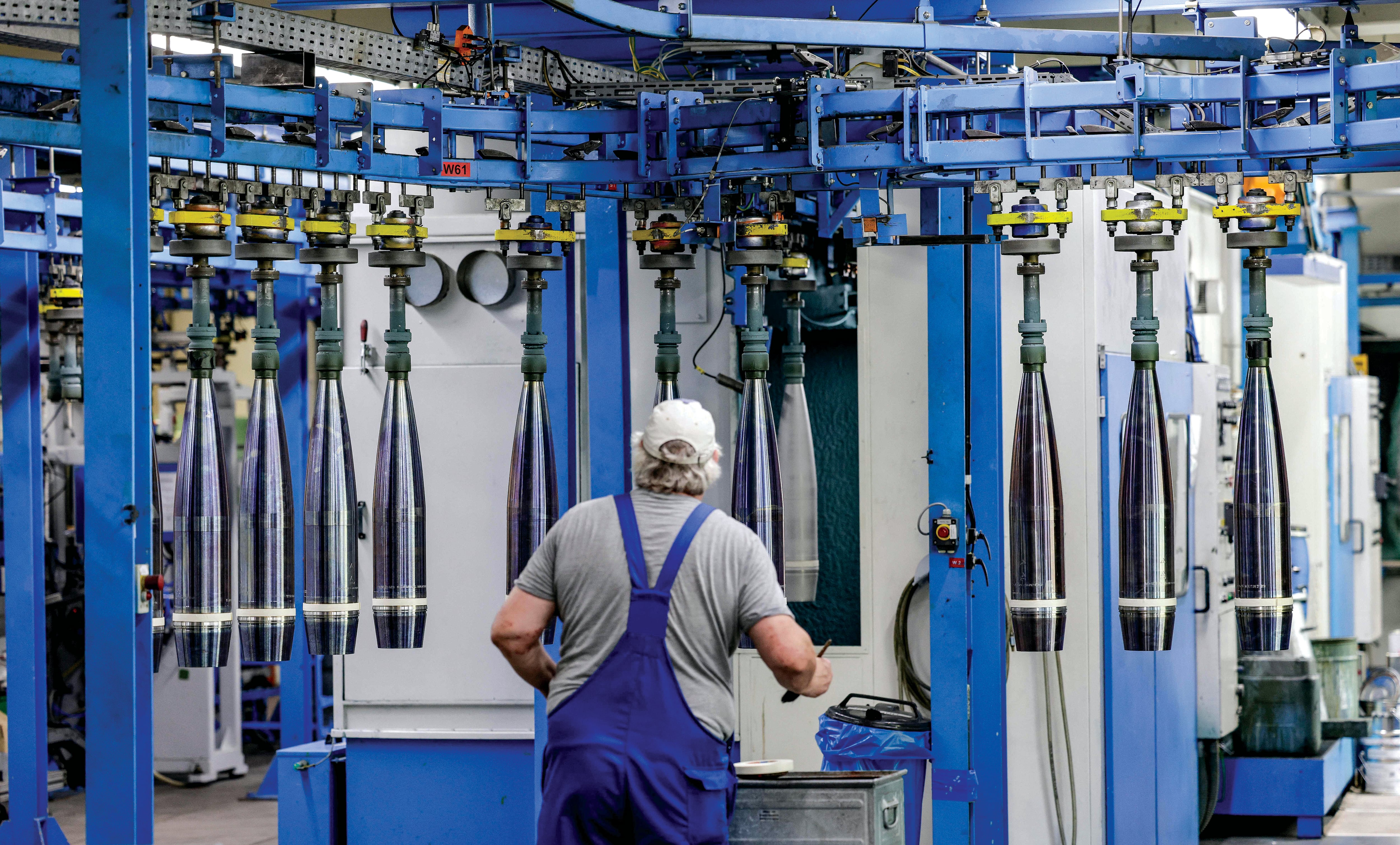

BERLIN — Germany’s high-tech defense firms are adapting their business practices amid the war in Ukraine, replacing the sector’s boutique approach with a greater focus on mass production, according to company officials.

The key factor now tends to be speed, officials said. How soon systems can be delivered and combat-ready trumps clients’ requests for custom tailoring.

“We have seen a fundamental change in our production philosophy,” Lothar Belz, company spokesperson for German sensor manufacturer Hensoldt, said. This stems in large part from the increased demand, he said. While in the past Hensoldt usually delivered fewer than five large radars per year, those numbers have now risen to over 15 annually. By 2025, the cadence is expected to be 20 per year, according to Belz.

Output from certain departments – such as remote sensing and electronic warfare – has increased threefold since the “Zeitenwende,” German Chancellor Olaf Scholz’s famous turn of phrase describing a continent no longer deemed at peace following Russia’s invasion of Ukraine.

About half of Hensoldt’s radar production is destined for Kyiv this year, Belz said.

It’s an example how “Zeitenwende” – which translates into something like turning point or watershed moment – is slowly seeping into Germany’s defense policy and industry apparatus.

The term also came with a financial component, most notably a €100 billion cash infusion to the German armed forces and a pledge to raise annual defense spending past the NATO target of 2% of GDP for the coming years. Scholz has called the measures “the most far-reaching change in German security policy since the Bundeswehr was founded in 1955.”

RELATED

Zeitenwende zeitgeist

Companies are feeling the time crunch. “We definitely had orders where the customer said: ‘At the end of the day, we don’t care about the exact color scheme that much,’” said Pitt Marx, spokesperson of Thales Germany. He explained that contracts previously were usually signed with some breathing room when it came to the production timeline. Now, the company has had to “bundle capacities” and assign some employees to projects they would not usually work on to meet objectives.

Thales’ customers receive their orders quicker than they would have a few years ago, Marx said. Similarly, at Hensoldt, radars are now delivered typically “within a year” of the contract, though exact timing still depends on “adaptation necessities,” Belz said.

To meet the new demands, Hensoldt has added a new shift and increased the size of its production staff by 15% in the past two years.

Strong hiring is happening throughout the industry. German radio specialist Rohde & Schwarz added almost 2,000 new employees, and the company also added a third shift, according to spokesperson Dennis-Peter Merklinghaus.

At Hensoldt, the dictate of the Zeitenwende has affected everything, ranging from production – “we now do industrial serial production,” Belz said – to the supply of components and even the handling of testing and the handoff of finished systems to customers.

Thales’ Marx said that when it came to delivery and the training of workers, the company had become “more pragmatic,” a term used frequently in several interviews conducted for this story to denote that certain standards had to be softened to make mission.

“There is a fundamental difference in whether you are ordering something to keep an eye on your border, or whether you’re deploying it right into an active warzone,” he said.

Pandemic aftershocks

Meanwhile, the industry is still feeling the aftershocks of the COVID-19 pandemic, whose supply chain disruptions never quite went away. It was mentioned as a concern in every interview Defense News conducted for this story.

For Rohde & Schwarz, retaining control of needed components has paid dividends, keeping deliveries on time even during the height of the global health crisis. “We can build everything from the smallest chips to ordinary server racks ourselves and do so within Germany,” Merklinghaus said.

Hensoldt’s Belz also emphasized the importance of supply chains. His company has made new investments in logistics, building a new warehouse and distribution center. This would have been unthinkable in the past, as the company would order components as they became necessary for the fulfillment of contracts. Now, it maintains stocks of crucial parts. In early December, Hensoldt announced the acquisition of the electronics and logistics company ESG.

RELATED

The greater need for speed may also require customers to recalibrate their expectations. In the past, it was common practice for government buyers to provide hundreds of pages and thousands of bullet points of individualized wishes for a contract, and even to change the requirements while production was already running, said Belz.

The shift toward producing larger quantities in shorter amounts of time “requires a thorough understanding of operational requirements on our part but also a certain amount of restraint from the customer,” he said. Not all those interviewed shared this philosophy but Hensoldt believes it’s the right move for a new era, the spokesperson said.

After all, he said, the key to success in the new, fast-paced world of European high-tech defense companies is “not just being willing to deliver, but being able to.”

Linus Höller is a Europe correspondent for Defense News. He covers international security and military developments across the continent. Linus holds a degree in journalism, political science and international studies, and is currently pursuing a master’s in nonproliferation and terrorism studies.